OUR CAPABILITIES

EXPERTISE, EXPERIENCE, AND KNOWLEDGE

Weatherford Aerospace possesses deep technical skills built across decades of experience coupled with in-depth, practical aerospace knowledge. We have invested in some of the largest tanks in the US, giving us the ability to handle our customers’ longest and widest components.

Questions about our Services?

Capabilities & Services

PROCESSING

We offer processing capabilities that includes anodizing, chemical filming and specialty coating, to meet most any specifications your designs require.

MACHINING AND FABRICATION

Weatherford Aerospace’s facilities possess the precision machining and fabrication capabilities to accommodate many needs, turning raw materials into finished detail parts. Our forming capability set includes hot-forming, cold-forming, roll forming, brake forming, and stress relief. We compliment our forming and chemical milling capabilities with up to 5-axis CNC routing and drilling of large sheet metal components.

NDI

(NON-DESTRUCTIVE INSPECTION)

We use fluorescent liquid penetrant inspection to identify cracks and imperfections with skill and ease, and perform hardness and conductivity testing.

PAINTING

Our paint booths can accommodate large parts such as wing skins. We have full capabilities for numerous primers, topcoats, and specialized coatings.

CHEMICAL MILLING

Weatherford’s pedigree in chemical milling, large tank capacity, and proprietary & recyclable maskant technology, gives us a cutting-edge ability to accommodate nearly all of our customers’ aluminum and titanium chemical milling needs.

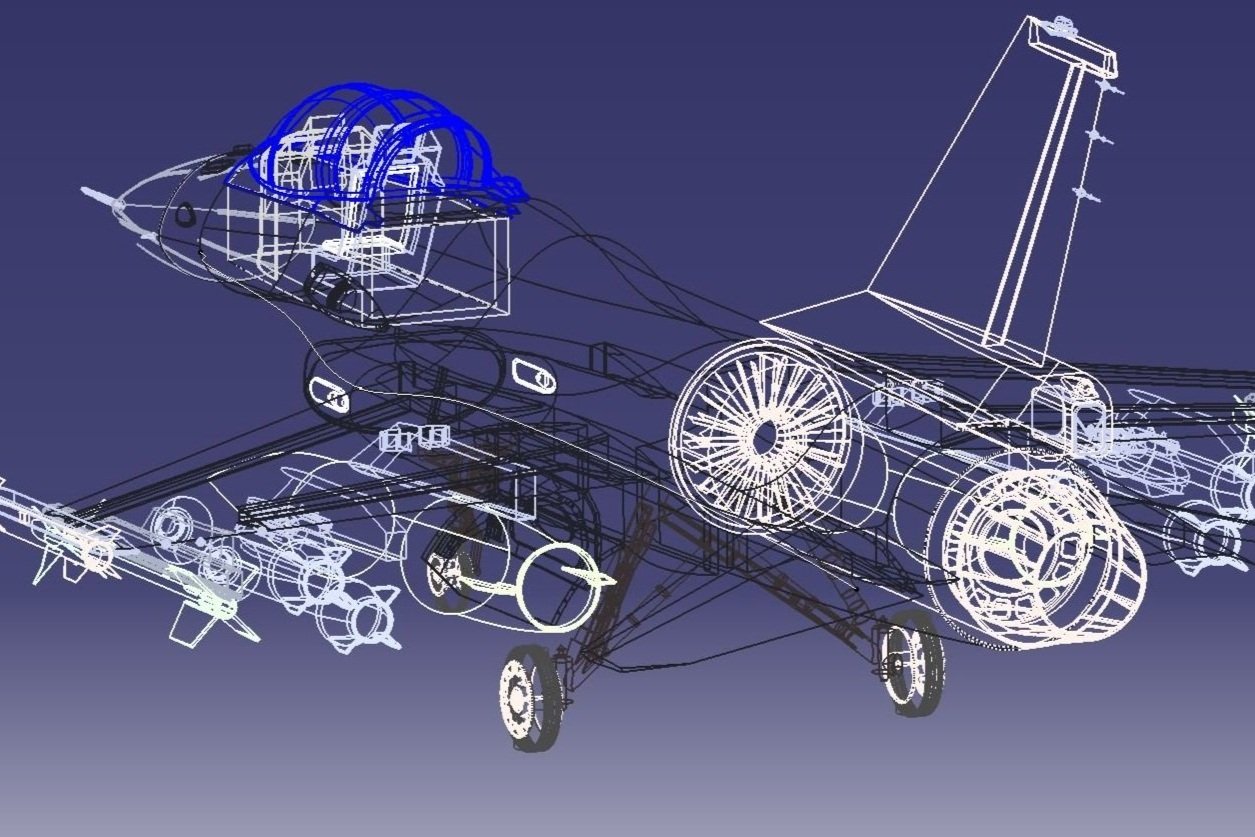

ENGINEERING

Our team possesses the technical skills to assist with tool design, product manufacturing methods, solid modeling, and complete part manufacturing.